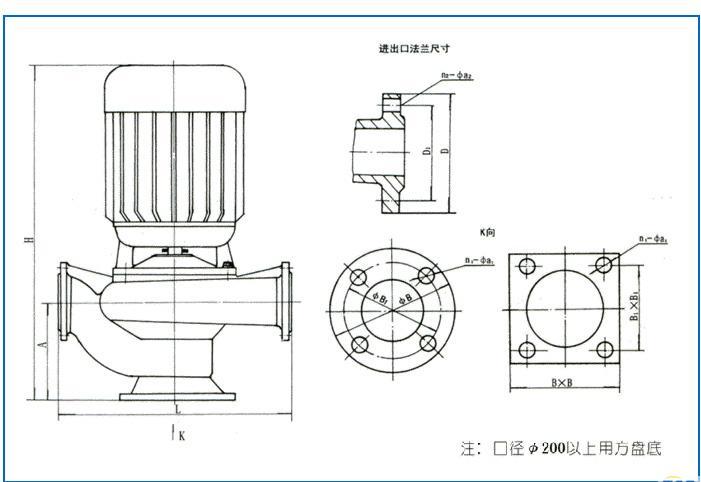

GWB型防爆管道排污泵安裝尺寸圖

浏覽次數:2014次發表時間:2013/2/21 21:23:59

GWB型防爆管道排污泵适用于化工(gōng)、石油、制藥、采礦、造紙(zhǐ)工(gōng)業、水泥廠、煉鋼廠、電(diàn)廠、煤加工(gōng)工(gōng)業,以及城市污水處理廠排水系統,市政工(gōng)程、建築工(gōng)地等行業輸送帶顆粒的污水、污物(wù)。

GWB型防爆管道排污泵産品特點:

1、管道排污泵與電(diàn)機直聯同軸,屬機電(diàn)一(yī)體(tǐ)化産品,結構緊湊,性能穩定。2、大(dà)流道抗堵塞水力部件設計,大(dà)大(dà)提高污物(wù)通過能力,能有效通過泵口徑的5倍纖維物(wù)質和直徑爲泵口徑約50%的固體(tǐ)顆粒。

3、設計合理,配套電(diàn)機合理,效率高,噪音低,節能效果顯著。

4、機械密封采用硬質耐磨碳化鎢,具有耐用、耐磨等特點,可以使泵安全連續運行8000小(xiǎo)時以上。

5、管道排污泵爲立式結構,進出口中(zhōng)心線在同一(yī)水平線上,且進出口法蘭規格相同,安裝拆卸十分(fēn)方便。

6、占地面積小(xiǎo),無需建機房,可節省大(dà)量基建費(fèi)用;在電(diàn)機風葉端加上防護罩,整機可置于室外(wài)工(gōng)作。

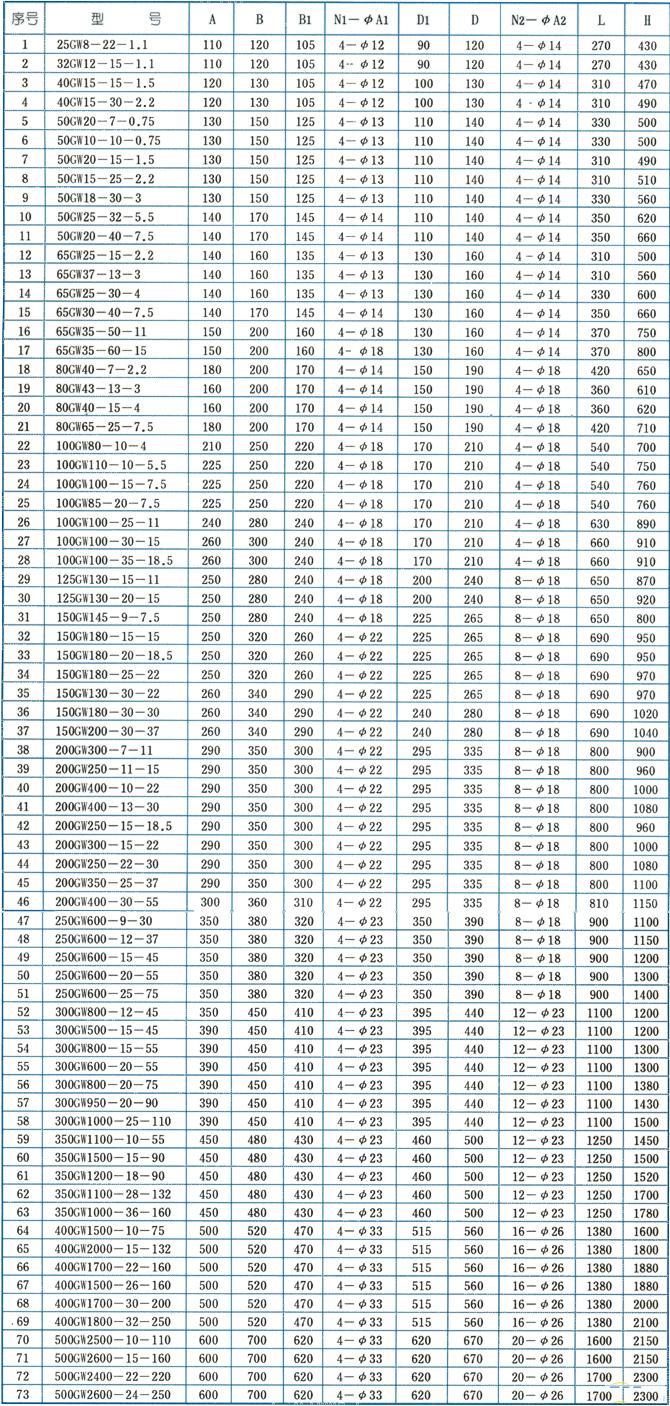

GW型管道式無堵塞排污泵技術參數:

流量:8-2600m3/h;

揚程:7-60m;

轉速:740-2900r/min;

口徑:φ25-φ500;

溫度範圍:-15-+60℃;

工(gōng)作壓力:≤1.0Mpa。

型号意義:

|

GW型管道式無堵塞排污泵性能參數

|

|||||||||

|

序号

|

型 号

|

口 徑

(mm) |

流 量(m3/h)

|

揚 程(m)

|

轉 速(r/min)

|

功 率(kw)

|

效 率

(%) |

水泵電(diàn)器控制器

|

自動耦合器配WQ

|

| 1 |

25GW8-22-1.1

|

25

|

8

|

22

|

2825

|

1.1

|

38.1

|

QZD-1.1

|

/

|

| 2 |

32GW12-15-1.1

|

32

|

12

|

15

|

2825

|

1.1

|

40

|

QZD-1.1

|

/

|

| 3 |

40GW15-15-1.5

|

40

|

15

|

15

|

2840

|

1.5

|

45.1

|

QZD-1.5

|

40

|

| 4 |

40GW15-30-2.2

|

40

|

15

|

30

|

2840

|

2.2

|

18

|

QZD-2.2

|

40

|

| 5 |

50GW20-7-0.75

|

50

|

20

|

7

|

1390

|

0.75

|

54

|

QZD-0.75

|

40

|

| 6 |

50GW10-10-0.75

|

50

|

10

|

10

|

1390

|

0.75

|

56

|

QZD-0.75

|

50

|

| 7 |

50GW20-15-1.5

|

50

|

20

|

15

|

2840

|

1.5

|

55

|

QZD-1.5

|

50

|

| 8 |

50GW15-25-2.2

|

50

|

15

|

25

|

2840

|

2.2

|

56

|

QZD-2.2

|

50

|

| 9 |

50GW18-30-3

|

50

|

18

|

30

|

2880

|

3.0

|

58

|

QZD-3.0

|

50

|

| 10 |

50GW25-32-5.5

|

50

|

25

|

32

|

2900

|

5.5

|

53

|

QZD-5.5

|

50

|

| 11 |

50GW20-40-7.5

|

50

|

20

|

40

|

2900

|

7.5

|

55

|

QZD-7.5

|

50

|

| 12 |

65GW25-15-2.2

|

65

|

25

|

15

|

2840

|

2.2

|

52

|

QZD-2.2

|

50

|

| 13 |

65GW37-13-3

|

65

|

37

|

13

|

2880

|

3.0

|

55

|

QZD-3.0

|

65

|

| 14 |

65GW25-30-4

|

65

|

25

|

30

|

2890

|

4.0

|

58

|

QZD-4.0

|

65

|

| 15 |

65GW30-40-7.5

|

65

|

30

|

40

|

2900

|

7.5

|

56

|

QZD-7.5

|

65

|

| 16 |

65GW35-50-11

|

65

|

35

|

50

|

2930

|

11

|

60

|

QZD-11

|

65

|

| 17 |

65GW35-60-15

|

65

|

35

|

60

|

2930

|

15

|

63

|

QZD-15

|

65

|

| 18 |

80GW40-7-2.2

|

80

|

40

|

7

|

1420

|

2.2

|

52

|

QZD-2.2

|

65

|

| 19 |

80GW43-13-3

|

80

|

43

|

13

|

2880

|

3.0

|

50

|

QZD-3.0

|

80

|

| 20 |

80GW40-15-4

|

80

|

40

|

15

|

2890

|

4.0

|

57

|

QZD-4.0

|

80

|

| 21 |

80GW65-25-7.5

|

80

|

65

|

25

|

2900

|

7.5

|

56

|

QZD-7.5

|

80

|

| 22 |

100GW80-10-4

|

100

|

80

|

10

|

1440

|

4.0

|

62

|

QZD-4.0

|

80

|

| 23 |

100GW110-10-5.5

|

100

|

110

|

10

|

1440

|

5.5

|

66

|

QZD-5.5

|

100

|

| 24 |

100GW100-15-7.5

|

100

|

100

|

15

|

1440

|

7.5

|

67

|

QZD-7.5

|

100

|

| 25 |

100GW85-20-7.5

|

100

|

85

|

20

|

1400

|

7.5

|

68

|

QZD-7.5

|

100

|

| 26 |

100GW100-25-11

|

100

|

100

|

25

|

1460

|

11

|

65

|

JJ1-11

|

100

|

| 27 |

100GW100-30-15

|

100

|

100

|

30

|

1470

|

15

|

66

|

JJ1-26

|

100

|

| 28 |

100GW100-35-18.5

|

100

|

100

|

35

|

1460

|

18.5

|

65

|

JJ1-18.5

|

100

|

| 29 |

125GW130-15-11

|

125

|

130

|

15

|

1460

|

11

|

62

|

JJ1-11

|

100

|

| 30 |

125GW130-25-15

|

125

|

130

|

20

|

1440

|

15

|

63

|

JJ1-15

|

125

|

| 31 |

150GW145-6-7.5

|

150

|

145

|

6

|

1470

|

7.5

|

63

|

QZD7.5

|

125

|

| 32 |

150GW180-15-15

|

150

|

180

|

15

|

1470

|

15

|

65

|

JJ1-15

|

150

|

| 33 |

150GW180-20-18.5

|

150

|

180

|

20

|

1470

|

18.5

|

75

|

JJ1-18.5

|

150

|

| 34 |

150GW180-25-22

|

150

|

180

|

25

|

1470

|

22

|

76

|

JJ1-22

|

150

|

| 35 |

150GW130-30-22

|

150

|

130

|

30

|

1470

|

22

|

75

|

JJ1-22

|

150

|

| 36 |

150GW180-30-30

|

150

|

180

|

30

|

970

|

30

|

73

|

JJ1-30

|

150

|

| 37 |

150GW200-30-37

|

150

|

200

|

30

|

970

|

37

|

70

|

JJ1-37

|

150

|

| 38 |

200GW300-7-11

|

200

|

300

|

7

|

1470

|

11

|

73

|

JJ1-11

|

150

|

| 39 |

200GW250-11-15

|

200

|

250

|

11

|

1470

|

15

|

74

|

JJ1-15

|

200

|

| 40 |

200GW400-10-22

|

200

|

400

|

10

|

1470

|

22

|

76

|

JJ1-22

|

200

|

| 41 |

200GW400-13-30

|

200

|

400

|

13

|

1470

|

30

|

73

|

JJ1-30

|

200

|

| 42 |

200GW250-11-15

|

200

|

250

|

15

|

1470

|

18.5

|

72

|

JJ1-18.5

|

200

|

| 43 |

200GW300-15-22

|

200

|

300

|

15

|

1470

|

22

|

73

|

JJ1-22

|

200

|

| 44 |

200GW250-22-30

|

200

|

250

|

22

|

1470

|

30

|

71

|

JJ1-30

|

200

|

| 45 |

200GW350-25-37

|

200

|

350

|

25

|

1470

|

37

|

75

|

JJ1-37

|

200

|

| 46 |

200GW400-30-55

|

200

|

400

|

30

|

1480

|

55

|

70

|

JJ1-55

|

200

|

| 47 |

250GW600-9-30

|

250

|

600

|

9

|

980

|

30

|

74

|

JJ1-30

|

250

|

| 48 |

250GW600-12-37

|

250

|

600

|

12

|

1480

|

37

|

78

|

JJ1-37

|

250

|

| 49 |

250GW600-15-45

|

250

|

600

|

15

|

1480

|

45

|

75

|

JJ1-45

|

250

|

| 50 |

250GW600-20-55

|

250

|

600

|

20

|

1480

|

55

|

73

|

JJ1-55

|

250

|

| 51 |

250GW600-25-75

|

250

|

600

|

25

|

1480

|

75

|

73

|

JJ1-75

|

250

|

| 52 |

300GW800-12-45

|

300

|

800

|

12

|

1480

|

45

|

76

|

JJ1-45

|

300

|

| 53 |

300GW500-15-45

|

300

|

500

|

15

|

980

|

45

|

70

|

JJ1-45

|

300

|

| 54 |

300GW800-15-55

|

300

|

800

|

15

|

980

|

55

|

73

|

JJ1-55

|

300

|

| 55 |

300GW600-20-55

|

300

|

600

|

20

|

980

|

55

|

75

|

JJ1-55

|

300

|

| 56 |

300GW800-20-75

|

300

|

800

|

20

|

980

|

75

|

78

|

JJ1-75

|

300

|

| 57 |

300GW950-20-90

|

300

|

950

|

20

|

980

|

90

|

80

|

JJ1-90

|

300

|

| 58 |

300GW1000-25-110

|

300

|

1000

|

25

|

980

|

110

|

82

|

JJ1-110

|

300

|

| 59 |

300GW1100-10-55

|

300

|

1100

|

10

|

980

|

55

|

84.5

|

JJ1-55

|

300

|

| 60 |

350GW1500-15-90

|

350

|

1500

|

15

|

980

|

90

|

83.1

|

JJ1-90

|

350

|

| 61 |

350GW1200-18-90

|

350

|

1200

|

18

|

980

|

90

|

83.2

|

JJ1-90

|

350

|

| 62 |

350GW1100-28-132

|

350

|

1100

|

28

|

740

|

132

|

78.5

|

JJ1-132

|

350

|

| 63 |

350GW1000-36-160

|

350

|

1000

|

36

|

740

|

160

|

82.1

|

JJ1-160

|

350

|

安裝尺寸圖:

上一(yī)篇: YG型防爆立式管道油泵結構圖

下(xià)一(yī)篇: FB、AFB型耐腐蝕離(lí)心泵結構圖